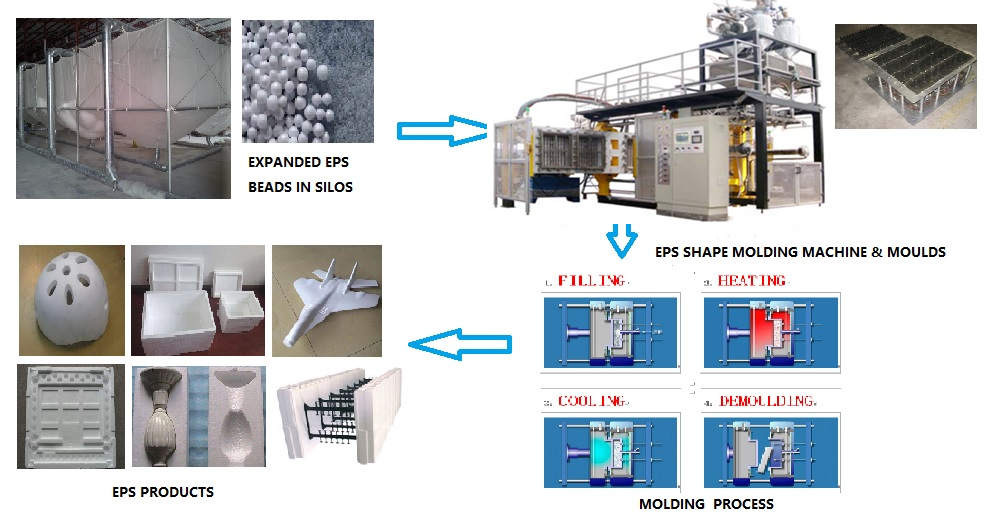

EPS LR Vacuum shape Molding Machine ESCX-LR1214

Size of mould: 1220*1420mm

Max. product size: 1200*1400mm

Max. product height: 420mm

Molding density: 12-50 KG/M3

Guide rod (diameter*length*quantity): ОҰ 85mmГ—2500mmГ—4

Oil cylinder (diameter*stroke): ОҰ125mmГ—1150mmГ—2

Stroke speed(about): >85mm/sec

Vacuum tank volume: 200L

Oil tank volume: >200L

Hopper volume: 65L*2

Total power: 16KW

Dimensioin: 7130*4800*4200mm

Weight: about 16000kg

Main characters

вҖў Omron PLC, touch screen and encoder

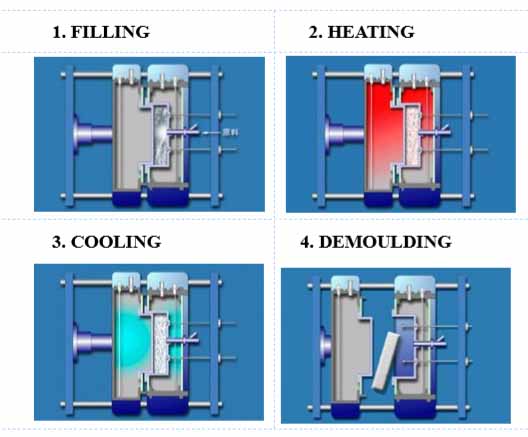

вҖў Quick pressurized filling & interval filling (2-3 seconds)

вҖў Large steam inlet & outlet to shorten molding cycle

вҖў Revolving steam conveying instead of rubber pipe make it more reliable

вҖў Quick connector design, fast mould change (around 20 minute)

вҖў Ball blast descaling, mould cavity coated with aluminium

вҖў Fully automatic electronic, hydraulic and pneumatic control

вҖў Fixed and movable mold match the standard frame

вҖў Fixed and movable mould block match water tank

вҖў Special design of one fixed mould & two moveable moulds, best for EPS products with inserted parts. Worker can insert extra parts into one moveable mould meanwhile the other moveable mould and fixed mould under molding process, no need stop machine for parts inserting, output capacity can be double more .

вҖў The moveable mould for parts inserting is on the side of machine, worker do not need go inside machine to insert, it is more safe for worker and easy for worker inserting.